–An Article by Poojan Patel

Celebrating World Bamboo Day- The Sustainability Debate of Bamboo Fabrics

Bamboo fabric offers sustainable fashion, but its chemical process and rayon association raise environmental concerns. World Bamboo Day calls for reflection.

Today, as we celebrate World Bamboo Day, it is the perfect occasion to delve into the eco-friendly allure of bamboo fabrics. Bamboo, often referred to as “green gold,” is celebrated for its remarkable qualities, such as rapid growth, strength, and flexibility. But is bamboo fabric truly as sustainable and eco-friendly as we might think?

The Green Side of Bamboo

Bamboo’s sustainability starts with its astonishing growth rate. This fast-growing grass can shoot up as much as four feet in a single day, releasing a staggering 35% more oxygen into the atmosphere compared to other trees of its size. What’s more, bamboo matures within a mere seven years, and its extensive root network continuously spawns new shoots, which aids in soil improvement and prevents erosion.

These attributes make bamboo cultivation seem like a boon for the environment. When it comes to fashion, bamboo fabric has made waves as the trendiest sustainable option. It’s softer than cotton, with a texture reminiscent of silk, making it a favorite for eco-conscious consumers. Additionally, bamboo garments have the added advantage of excellent moisture absorption, making them ideal for summer wear and quick drying, which extends to bedding, towels, and rugs.

The Eco-Friendliness Debate

However, the sustainability and eco-friendliness of bamboo fabric are subject to a contentious debate. Critics argue that the process of transforming bamboo into fabric takes a toll on the environment, diminishing its eco-friendly credentials. Bamboo fabrics are produced using two primary methods: mechanical and chemical processes.

The mechanical process, akin to producing linen from flax or hemp, involves crushing the bamboo plant and employing natural enzymes to extract fibers. While this process yields bamboo linen, it’s costly and labor-intensive, resulting in limited production.

In contrast, most bamboo fabrics labeled as eco-fashion utilize a chemical process. Bamboo leaves and woody shoots are dissolved with potent chemical solvents like sodium hydroxide and carbon disulfide. This process, known as hydrolysis alkalization, raises serious health concerns, as both chemicals can harm the environment and human health. Carbon disulfide can lead to neural disorders and reproductive issues, while sodium hydroxide causes skin and eye allergies. Moreover, around half of the chemicals used are not recovered but discarded into the environment, exacerbating the pollution problem.

Some companies claim that their bamboo clothing is 100% eco-friendly and retains the antimicrobial properties of bamboo. However, it’s often revealed that these garments are not made from pure bamboo fibers but are, in fact, rayon—a synthetic material processed using toxic chemicals.

Rayon is derived from plant cellulose, including bamboo, and involves the use of chemicals that emit harmful gasses. This process effectively destroys the natural antimicrobial properties of bamboo. So, while bamboo fabric may appear eco-friendly, it’s not as pure or sustainable as it seems.

A Quest for Genuine Eco-Fashion

Considering these concerns, consumers looking to purchase bamboo garments should seek certifications from reliable entities like Oeko-Tex, Soil Association, SKAL, or KRAV. The Oeko-Tex label is currently considered the most trustworthy indicator of healthy clothing choices, though it doesn’t guarantee sustainable and eco-friendly manufacturing processes.

In conclusion, bamboo, classified as grass, could be the world’s most eco-friendly resource, but its transformation into fabric using toxic chemicals raises significant environmental and health concerns. To make truly sustainable choices, consumers must navigate the bamboo fabric market carefully and seek certification from credible organizations. As we celebrate World Bamboo Day, let’s remember that while bamboo holds immense potential, it’s essential to tread carefully in the quest for genuine eco-fashion.

Bamboo vs. Cotton: A Sustainability Comparison

To understand the eco-credentials of bamboo fabric fully, it’s important to compare it to another popular textile: cotton. Bamboo has the upper hand in raw material production. It is naturally pest-resistant and requires no fertilizers, making it more eco-friendly than conventional cotton. Additionally, bamboo consumes less water than organic cotton, further boosting its sustainability profile.

However, the sustainability of the final product hinges on how bamboo clothing is made. Currently, there are three primary types of bamboo cloth:

- Conventional Viscose Bamboo Rayon: While greener than traditional rayon, this method still relies on a chemical-intensive process, involving carbon disulfide and sulfuric acid.

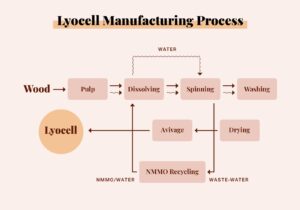

- Lyocell Process Bamboo Rayon: Developed by Lenzing Industries, this method recycles chemicals and water, reducing environmental impact.

- Bamboo Linen: This process involves mechanical processing, requiring significantly fewer resources and chemicals.

So, while bamboo excels in raw material production, the sustainability of the final product depends on the manufacturing process.

The Evolution of Bamboo Fabric

The history of bamboo fabric is a fascinating journey. Bamboo has a long-standing history of use in Asia for paper, weapons, and household articles. However, it only entered commercial markets as fabric in the early 2000s. The experimentation and refinement of this invention span over a century.

The earliest U.S. patents related to bamboo fabric date back to 1864 when Philipp Lichtenstadt sought to create a process for using bamboo fiber in manufacturing. However, this endeavor failed to gain traction due to low demand for bamboo and high transport costs from Asia.

In 2001, Beijing University achieved the milestone of successfully transforming bamboo into cloth. The advent of new-age solvents and special dying processes made it possible to produce high-quality bamboo fabric at affordable prices. This coincided with a growing demand for sustainable textiles, propelling bamboo fabric into the mainstream.

The Manufacturing Journey

From stem to cloth, the production of bamboo fabric starts with crushing the soft inner pith of the bamboo trunk, followed by soaking for 12-24 hours. The solution is then pulped, separated into thin threads of fiber, spun, dyed, and woven into fabric. The result is a silky-soft material known for its comfort and eco-friendly properties.

In conclusion, bamboo fabric’s journey from being a largely unknown material to a sought-after sustainable option is a testament to the textile industry’s evolving landscape. While bamboo holds great promise for a greener future, it’s vital to scrutinize the manufacturing processes to ensure the sustainability and eco-friendliness of the final product. On this World Bamboo Day, let’s celebrate the potential of bamboo while continuing to question and improve its sustainability credentials in the world of fashion.